Contact

and support

or contact Flexit for guidance.

Flexit GO is the app that lets you control Flexit Nordic ventilation units and the EcoNordic indoor climate system directly from your mobile phone. You get a clear overview of the indoor climate and can adjust ventilation—both at home and when you’re away.

Flexit Select is Flexit’s digital ventilation calculation tool—designed for professional planning and dimensioning.

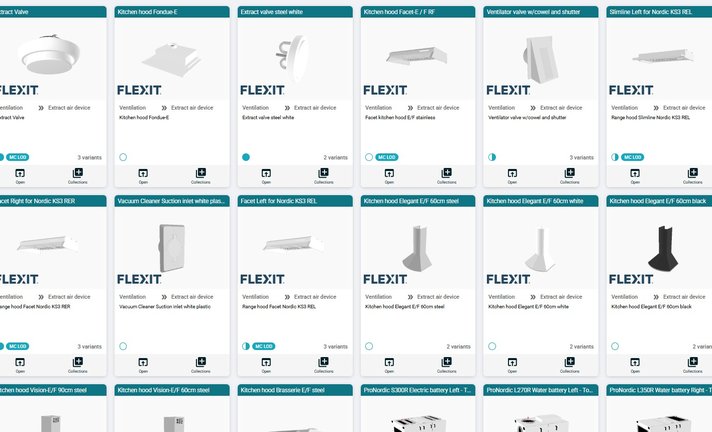

Flexit makes it easy to design ventilation using BIM. Our products are available as quality-assured BIM objects in MagiCAD Cloud—ready to use in your projects.

Healthy indoor air quality is essential in buildings where people live, learn and work. This page explains how Nordic performance principles ensure reliable, energy-efficient ventilation in vital indoor environments – adapted to climate, regulations and real-world use.

Previous searches:

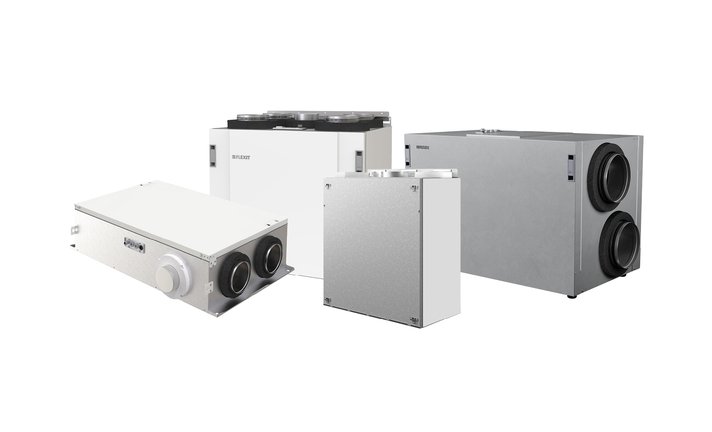

From the very beginning, our goal has been the same: to give people a better indoor climate through safe, energy-efficient, and future-oriented solutions. With solid expertise, modern technology, and strong values, Flexit has grown into a leading player in the Nordic region.

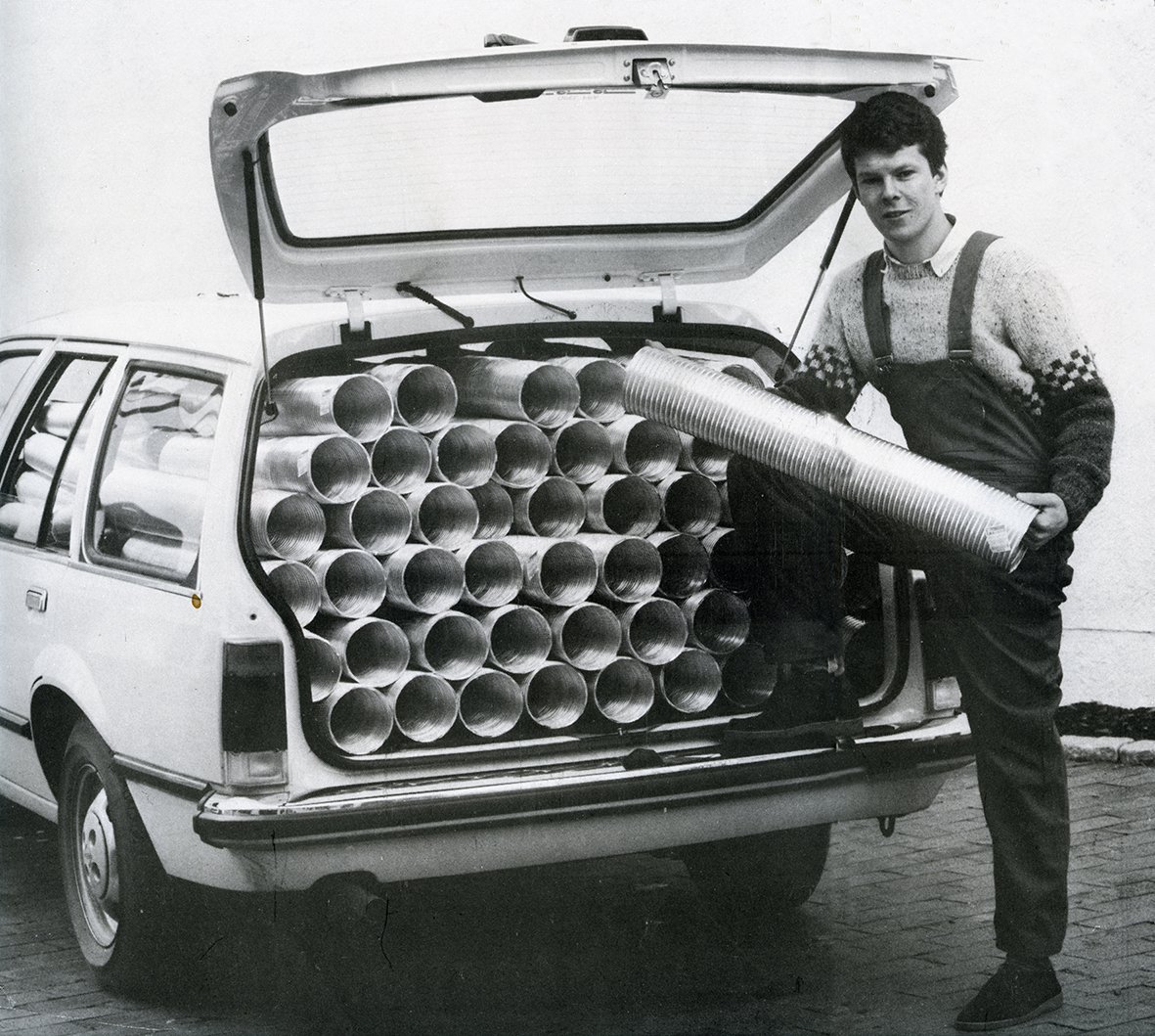

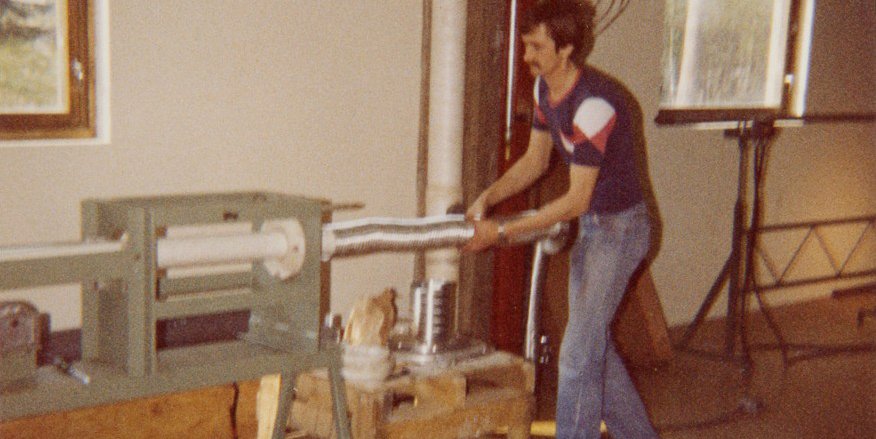

When Flexit was established in the 1970s, we started with simple wall vents at a time when buildings were far less airtight than they are today. As housing standards and energy requirements increased, we developed mechanical exhaust systems, before later taking the step into energy-efficient ventilation systems with heat recovery and control systems for both new and existing homes.

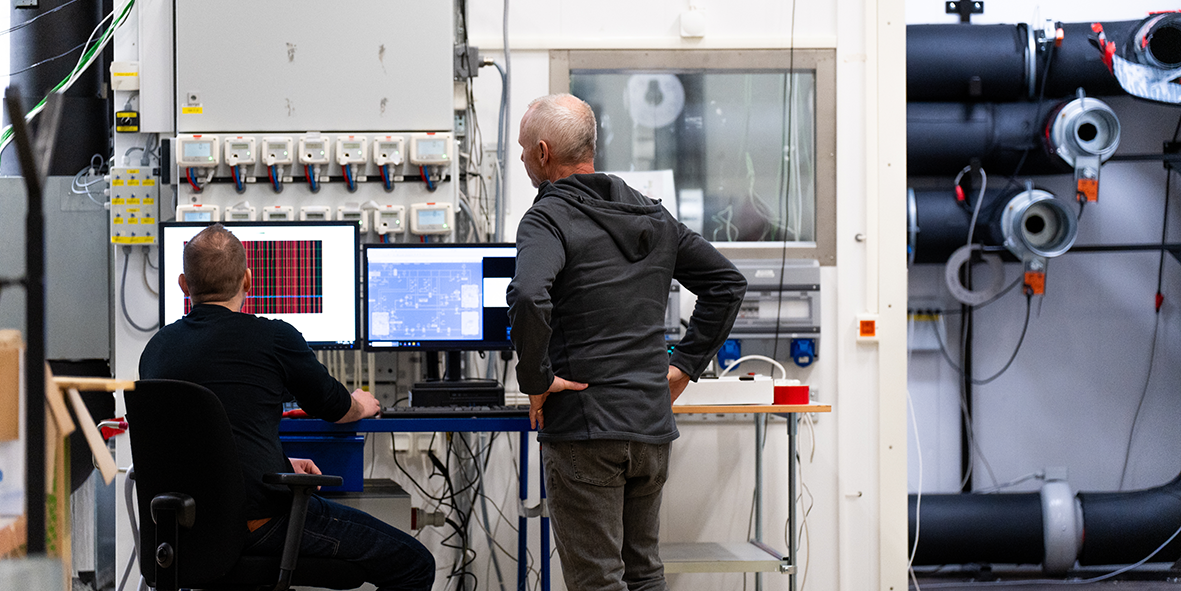

For decades, we have worked closely with leading research institutions such as SINTEF. Our ability to innovate has resulted in patents, industry standards, and technologies that have left a clear mark on the sector.

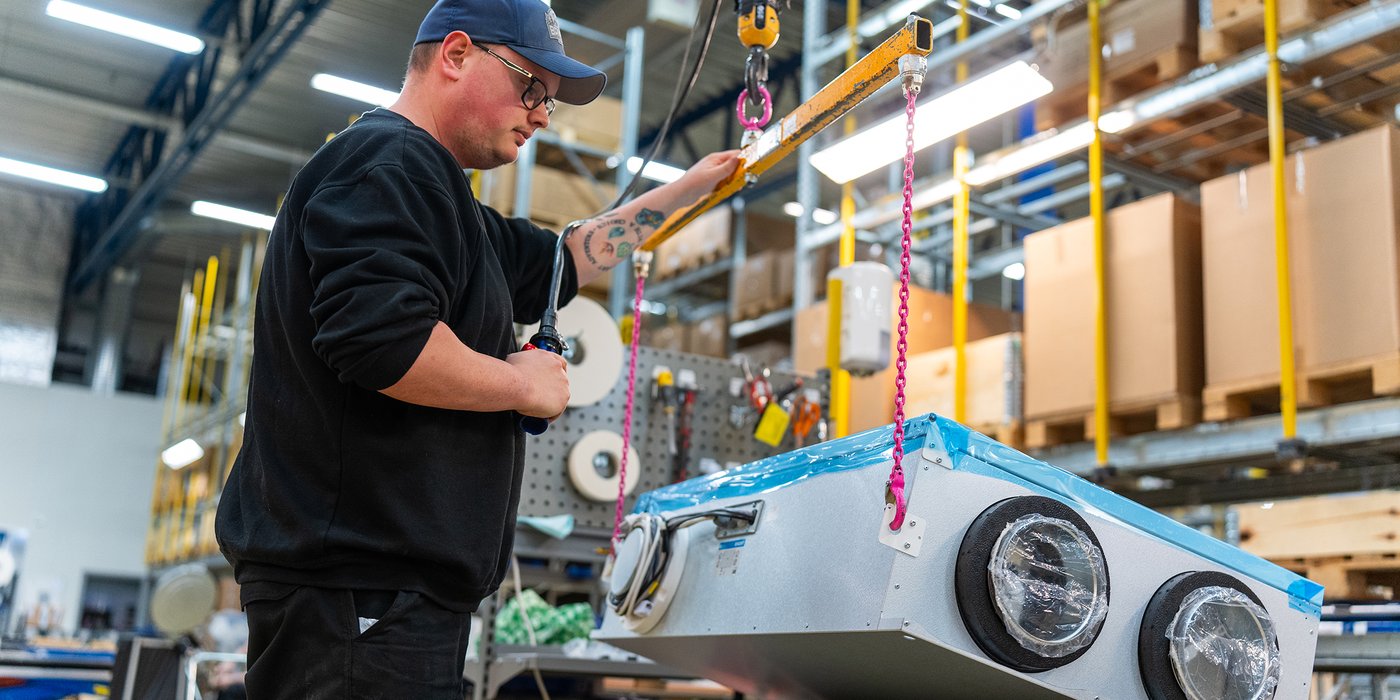

We develop and manufacture our solutions in Norway and Sweden, with close proximity between product development, laboratory testing, production, and the market. This ensures high quality, precise deliveries, and short decision-making processes. Our local presence also makes us a partner with in-depth knowledge of the climate, building traditions, laws, and regulations of the Nordic market—and therefore of the requirements placed on indoor climate solutions.

Flexit is built on four core values that shape everything we do: trustworthy, energetic, innovative, and considerate.

We trust and support one another, and we work purposefully to make everyday life a little better for our customers—whether they are private homeowners, contractors, housing developers, or retailers.

Buildings are changing, and the requirements for energy efficiency, indoor climate, and documentation are becoming increasingly stringent. Flexit therefore invests in advanced laboratories, research, and the continued development of technology to support solutions for future buildings. We aim to be a trusted partner in the green transition—and a driving force behind solutions that deliver better health and lower energy consumption.