Contact

and support

or contact Flexit for guidance.

Flexit GO is the app that lets you control Flexit Nordic ventilation units and the EcoNordic indoor climate system directly from your mobile phone. You get a clear overview of the indoor climate and can adjust ventilation—both at home and when you’re away.

Flexit Select is Flexit’s digital ventilation calculation tool—designed for professional planning and dimensioning.

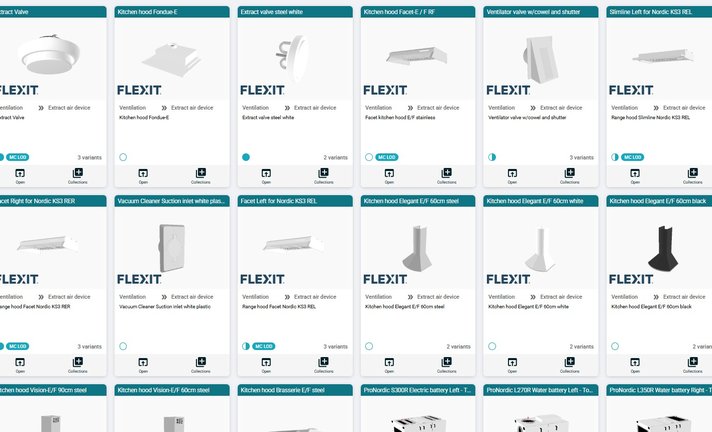

Flexit makes it easy to design ventilation using BIM. Our products are available as quality-assured BIM objects in MagiCAD Cloud—ready to use in your projects.

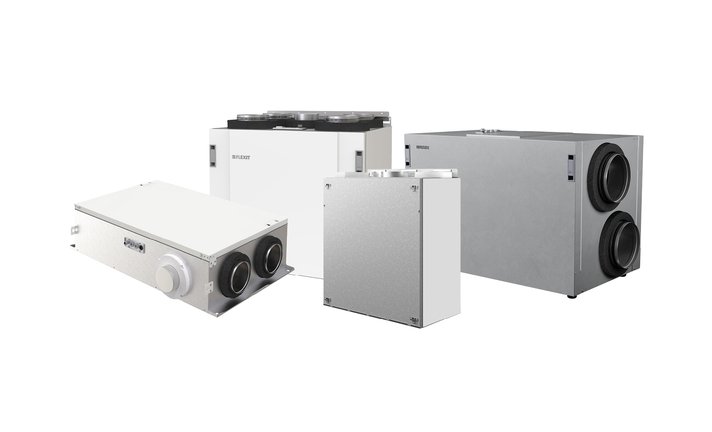

Healthy indoor air quality is essential in buildings where people live, learn and work. This page explains how Nordic performance principles ensure reliable, energy-efficient ventilation in vital indoor environments – adapted to climate, regulations and real-world use.

Previous searches:

A ventilation filter does more than just trap dust. It protects both people and technical components. This is equally important for homeowners, contractors, maintenance personnel, and distributors.

Choosing the right ventilation filter is about documentation, test results, and proper fit—not price. All Flexit filters must meet the following requirements:

Filter class

Meet ePM1 50–85% for both supply and extract air, documented through accredited laboratory testing.

Performance over time

Maintain filtration efficiency throughout the entire service life (typically 6–12 months). Performance measured only on a new filter is not sufficient documentation.

Quality assurance and testing

Ensure consistent production quality and be tested in the specific Flexit ventilation unit. This guarantees correct pressure drop, service life, and function under real operating conditions.

Pressure drop and sealing

Pressure drop, fit, and sealing around the filter must be tested and documented to prevent air leakage and imbalance in airflow.

Eurovent certification

Please note that general Eurovent certification alone is not sufficient. The filter must be tested in the relevant Flexit ventilation unit to ensure correct real-world performance.

Using unsuitable filters can lead to several well-known issues:

Filters that appear similar or have the same filter class can behave very differently in a ventilation unit.

Residential ventilation units have compact physical dimensions and demanding airflow conditions, making laboratory testing alone insufficient.

The filter must:

This ensures the correct indoor climate, low energy consumption, and stable operation—while reducing the risk of imbalance, moisture issues, and technical damage.

Multiple industry sources and recommendations from independent organizations emphasize the importance of choosing quality filters over low-cost alternatives. This applies equally to health, technical performance, and energy efficiency.