FAQ

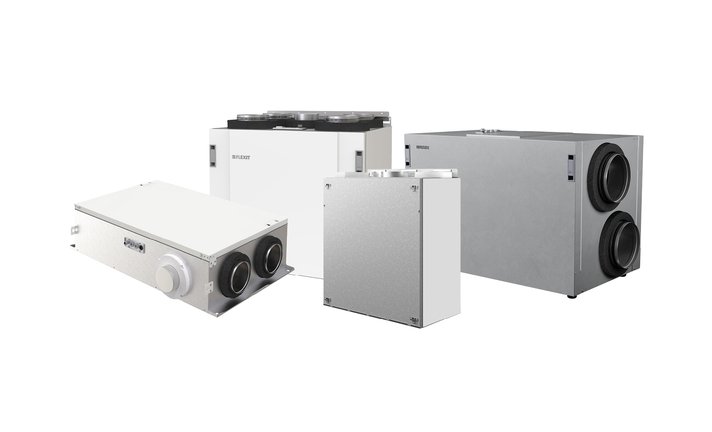

Can I control the central exhaust unit (ULV, USV, USVX) using a switch instead of the kitchen hood?

Yes, central exhaust units of type ULV, USV and USVX can be controlled using a switch instead of via the kitchen hood. For this purpose, you can use a 3-speed switch with article number 09257. This allows simple and stable control of the fan speed directly from the switch.

Can I perform basic maintenance on my ventilation system myself?

Yes, basic maintenance can be carried out yourself if you are reasonably technically inclined and know what needs to be done. What type of maintenance can be performed, and how it should be done correctly, is described in the user manual for your product. By following the user manual, you ensure correct execution and safe operation of the ventilation system.

Can the wall hood be turned?

Yes, in many cases the wall hood can be turned, provided this is permitted in the installation instructions for the specific model. It is important that the ducts are still connected correctly and that any drainage and function are maintained as described by the manufacturer. Installation must always be carried out in accordance with the applicable installation instructions to ensure correct operation.

Can we get a routine or guideline for the use of low-profile ventilation ducts?

Routines and recommendations for the use of low-profile duct systems are described in Flexit’s brochures and installation manuals for the relevant duct solutions. These documents provide the necessary information on correct design, installation and use. To assess whether low-profile ducts are suitable for your project, we recommend contacting Flexit for guidance based on the specific project conditions.

My 3-speed switch 09257 is not working – what could be the cause?

If the 3-speed switch 09257 is not working, you should check the capacitors inside the switch. Defective capacitors can prevent the switch from controlling the speed levels as intended. The correct run capacitor has article number 121840.

My central vacuum does not start – what could be the cause if I do not hear a clicking sound from the relay?

If the central vacuum does not start and you do not hear any clicking sound from the relay, this indicates that the start signal is not reaching the motor. In such cases, the control board is usually defective and must be replaced.

My central vacuum starts but stops after a short time – what could be the cause?

When the central vacuum starts and stops after a short time, this is often caused by partial or complete blockages in the ducting or hose. This restricts airflow, which can cause the motor to overheat. To protect the motor, the overheating protection will activate and shut down the vacuum. Check the hose and ducting for blockages and ensure free airflow before using the vacuum again.

My central vacuum has poor suction – what could be the cause?

Poor suction performance in a central vacuum system is often caused by partial or complete blockages in the ducting or hose. This may be due to accumulated dust, debris, or foreign objects in the system. It is recommended to check both the hose and the pipes for blockages and ensure free airflow throughout the entire system.

My central exhaust unit (ULV, USV, USVX) does not run at all speed levels – what could be the cause?

If a central exhaust unit of type ULV, USV or USVX does not operate at all speed levels, the most likely cause is a defective run capacitor. A local, authorised electrician can assist with replacing this component. The run capacitor has article number 101318 and is installed in the controller box near the motor.

My central exhaust unit (ULV, USV, USVX) is noisy – what can I do?

If a central exhaust unit of type ULV, USV or USVX is making noise, this is usually because the fan is dirty. The fan should be cleaned at least once a year.Start by unplugging the unit from the dedicated socket so that the fan is completely disconnected from the power supply. The connection box is attached with Velcro and should be carefully detached from the fan side.Next, loosen the four mounting screws on the round motor plate. The entire fan can now be pulled straight out of the fan housing by holding the square connection box.The fan unit can be taken to the kitchen or laundry room for cleaning. Use a non-water-based degreasing agent together with a small scraper or brush to remove stubborn dirt from the fan wheel. Be careful not to damage or deform the fan wheel, and make sure that no liquid enters the motor itself.Allow the fan to dry completely before carefully reinstalling it in the reverse order.